1. Give brief introduction about preliminary treatment.

The objective of preliminary Treatment is removal of the coarse solids & other large material often found in raw wastewater.

Removal of these material is necessary enhance The operation and maintenance of subsequent treatment units.

Preliminary Treatment Operations typically include coares screening, Grid Removal and in some cases, communication of large objects.

In Grit Chamber, The velocity of the water through the chamber is maintained sufficiently high or air is used, so as to prevent the settling of most organic solids.

Grit removal is not included as preliminary treatment step in most small wastewater treatment plants.

Comminutors are sometime adopted to supplement corous screening and serve to reduce the size of large particle so that they will be removed in the form of sludge in subsequent treatment process.

Slow measurement device often sending-waves flumes, are always included priliminary treatment stage.

2. Explain the purpose of Grit chamber.

The purpose of Grit chamber is to separate gravel and sand and other mineral material down to diameter between 0.2 to 0.1 mm.

Grit chamber are provide to,

- Protect Downstream Moving Mechanical equipment.

- Reduce Formation of heavy deposit in the pipelines and channels.

- Reduce The Frequency of digestor cleaning caused by excessive accumulation of grit.

- To increase the overall efficiency of sewage treatment plant (STP).

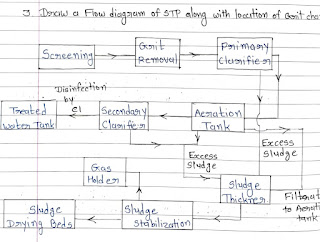

3. Draw a Flow Diagram of STP along with location of Grit chamber.

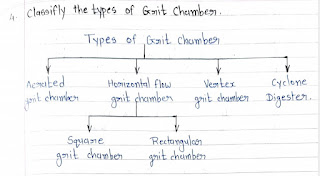

4. Classify The Types Of Grit Chamber.

Types of Grit chamber

- Aerated Grit chamber

- Horizontal flow Grit chamber ( Square Grit chamber and rectangular Grit chamber )

- Vertex Grit chamber

- Cyclone Digester

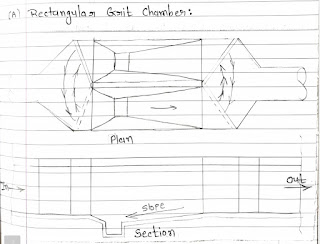

5. Draw a neat sketch of horizontal flow Grit chamber and explain in detail.

(A) Rectangular Grit chamber :

It is Oldest type of Grit chamber.

This Units are designed to maintain a velocity close to 0.3 m/s and to provide sufficient time for Grit particles to settle to the bottom of the tank.

This Designed velocity will carry most of organic particles through the tank and inorganic or heavier particles or grit will settle and disposed out from the chamber.

The length of the tank will be governed by the depth required by the settling velocity and control section.

Grit Removal from this type of accomplished by the screw conveyor along with scrapers.

In a small plant this types of Grit chamber are sometime cleaned manually.

Advantage- Uniform Flow distribution in possible with more number of channels.

- Simple Construction and Easy To Build.

- It Is a Difficult to manage and velocity 0.3 m/s over all wind range of flow.

- Had loss is more.

(B) Square Grit Chamber :

In a square Grit Chamber the effluent to unit is distributed over cross section of tank by series of gates and vanes and distributed wastewater flow in straight line across the tank.

Where the square Grit chamber are used, it's advisable to use at least 2 units.

This Types of units are large designed on the basis of the overflow rate that are dependent on particle size.

This Types of great chamber is removed 95% of 0.15 mm diameter particle at peak flow.

This settled grit are removed by rotating raking mechanism, in which the settled grit moved up by reciprocating racks and to be pumped out from tank.

The concentrated did maybe washed again and again, then organic materials flow back into the chamber.

Advantages

- Minimum Had Loss.

- Remove 95% Of 0.15 mm Diameter particles at peak flow.

Disadvantage

- Difficult to Achieve Uniform Flow at Wind Range Of Flow.

- At Low flows It Remove Large quantity of organic matter.

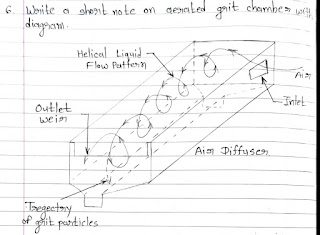

6. Write a short note on aerated Grit chamber with diagram.

In aerated grit chamber, air is introduced on side of a Rectangular tank to create a spiral or helical flow patterns which is perpendicular to the flow through the tank.

Heavier Grit particles have settling velocity settle at the bottom of tank, light particles remain in the suspension and passes through tank.

If the velocity is too high in the tank, Grit will be carried out of the chamber if it is too low organic material will be removed by grit.

The Quantity of air is easily adjusted with proper adjustment 100% removal will be obtained.

Settle great need washing, if Grid is not well washed i.e. it contents small amount of organic matter is creating and order problem and attract to insects.

Aerated Grid chamber are nomially design to remove 0.21 mm diameters of large Particles with 2 to 5 minutes of detention time.

For a great removal aerated Chambers are often provide with bucket evolution which are travelling on monorails and centred over the great collection and strong through.

Major advantages of Grit removal is that dropping of grid from bucket through the Grit Tank content.

Other installations equipped with bucket coverages which move the Grit to one end to other through and elevated it above the wastewater level in a continuous operation.

Advantage :

- Consistent removal efficiency over wind range of flow.

- Relatively low organic matter maybe removed.

- Performance of downstream unit maybe important by using pre-aeration to reduce septic condition in incoming waste water.

- Aerated grid chamber are versatile, allowing for chemical addition mixing pre aeration and Floccution.

Disadvantages

- Power Consumption is More

- Maintenance Cost is High

- Control of aeration system required additional labour or skill manpower.

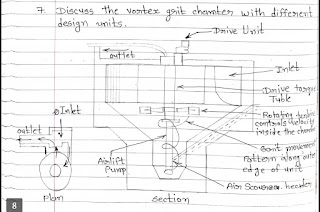

7. Discuss the water Grit chamber with different design Unit.

Grit is also remove in device that used a vertex flow pattern.

In this Grit chamber the wastewater enter and exit tangentially.

The Rotating impeller maintain constant flow velocity and its adjustable blades promoted separation of organic from grit.

The action of the propeller produce a to roidal flow path for grade particles.

The Grit settle by gravity into the Hopper in one revolution of the basin contents.

Settled Grit along with small amount of organic matter is sent to cyclone degriters for the removal of remaining organic materials

Remove greet may be devotering after the separation.

Advantage

- Remove High percentage of grit from wastewater.

- High removal efficiency.

- small footprint.

- Require less power than the aerated grit chamber.

- less maintenance cost.

Disadvantage

Propeller blades can collect range and damage to turbine or motor

Modification on system are very difficult at a later stage.

.jpg)

0 Comments