Q.1

(A) Explain objective of biological treatment of wastewater treatment of wastewater.

The objective of biological treatment in wastewater treatment is to remove pollutants from the water by using microorganisms to break down and digest the organic matter. This process can occur in aerobic or anaerobic conditions, depending on the specific treatment system being used.

The microorganisms consume the organic matter, converting it into biomass and carbon dioxide, which results in the removal of harmful pollutants from the water. This treatment method can be effective in reducing the levels of nitrogen and phosphorus, as well as other organic pollutants, and can also be used as a pretreatment step prior to physical or chemical treatment.

(B) Classify various types of microorganism used for Biological.

There are several types of microorganisms that are commonly used for biological treatment of wastewater, including:

Bacteria: These are the most common microorganisms used in biological treatment systems. They can be aerobic or anaerobic and can be used to break down a wide range of organic compounds.

Fungi: These microorganisms can also be used to break down organic matter and are often used in conjunction with bacteria in treatment systems.

Algae: These microorganisms can be used to remove nutrients, such as phosphorus and nitrogen, from wastewater. They are often used in constructed wetlands.

Protozoa: These microorganisms are a type of single-celled organism that can be used to consume bacteria and other microorganisms in wastewater treatment systems.

Rotifers: These are small multicellular organisms that feed on bacteria and other microorganisms, they are often used in secondary treatment systems.

Molds and Yeasts: These microorganisms can be used to treat industrial wastewaters containing high levels of organic matter.

It's important to note that the type of microorganism used in a wastewater treatment system will depend on the specific characteristics of the wastewater and the treatment goals.

(C) Difference between COD and BOD and highlight factor affecting on BOD test.

COD (Chemical Oxygen Demand) and BOD (Biochemical Oxygen Demand) are two different measures of water pollution. Both tests measure the amount of oxygen required to break down organic matter in water, but they do so in different ways:

COD: The COD test measures the amount of oxygen required to chemically oxidize all organic compounds in a water sample. It is a measure of the total organic content of water, including both biodegradable and non-biodegradable compounds.

BOD: The BOD test measures the amount of oxygen required by microorganisms to break down biodegradable organic matter in a water sample. It is a measure of the amount of organic matter that can be broken down by microorganisms.

There are several factors that can affect the results of a BOD test, including:

Temperature: The temperature of the water sample can affect the rate of microbial activity, and thus the BOD. Warmer temperatures will typically result in higher BOD values.

pH: The pH of the water sample can affect the activity of microorganisms, with optimal conditions being neutral (pH 7). Extreme pH values can inhibit the microbial growth.

Dissolved Oxygen: The amount of dissolved oxygen in the water sample can affect the results of the BOD test. High dissolved oxygen levels can lead to higher BOD values.

Nutrients: The presence of nutrients, such as nitrogen and phosphorus, can affect the growth of microorganisms and thus the BOD. High nutrient levels will typically result in higher BOD values.

Microbial Community: Different microbial communities can have different levels of ability to decompose organic matter. The type of microorganisms present in a sample can affect BOD values.

In summary, COD measures the total amount of organic matter in water, while BOD measures the amount of organic matter that can be broken down by microorganisms, which is more relevant in determining the water's ability to support aquatic life. BOD test results can be affected by various factors, such as temperature, pH, dissolved oxygen, nutrients, and microbial community.

Q.2

(a) Classify various Types of Biological Treatment technologies with example.

There are several types of biological treatment technologies that are commonly used in wastewater treatment, including:

Activated Sludge Process: This is one of the most widely used biological treatment methods. It involves the use of microorganisms, typically bacteria, to break down organic matter in wastewater. The microorganisms are suspended in the wastewater and are aerated to provide oxygen for growth. The resulting sludge is then removed and treated.

Trickling Filters: This type of biological treatment involves the use of a bed of filter media, such as rocks or plastic balls, which are colonized by microorganisms. Wastewater is trickled over the media and the microorganisms remove pollutants as the water passes through.

Rotating Biological Contactor: This type of biological treatment involves the use of a rotating wheel or disc that is covered with microorganisms. The wheel or disc is rotated through the wastewater and the microorganisms remove pollutants as they come into contact with the wastewater.

Upflow Anaerobic Sludge Blanket (UASB) Reactor: This technology uses anaerobic bacteria that decompose organic matter in absence of oxygen. Sludge and wastewater are mixed together in a reactor and the bacteria break down the organic matter. The treated water is then discharged and the sludge is removed and treated.

Membrane Bioreactor (MBR) : This technology involves the use of microfiltration or ultrafiltration membrane to separate microorganisms from the treated water. It's a combination of biological treatment and physical filtration.

Constructed wetland: This technology involves the use of plants, such as cattails or bulrushes, and microorganisms to remove pollutants from wastewater. The wastewater is passed through a constructed wetland and the plants and microorganisms remove pollutants as the water flows through.

Aerated Lagoon: This technology involves the use of a large pond or lagoon that is aerated to provide oxygen for the growth of microorganisms. Wastewater is discharged into the pond and the microorganisms remove pollutants as the water flows through.

These are some of the most common biological treatment technologies, and each has its own advantages and disadvantages. The specific technology chosen will depend on the characteristics of the wastewater being treated, the treatment goals, and the available resources.

(B). Define the following terms ;

I. Biomass yield :

Biomass yield refers to the amount of organic material, typically measured in dry weight, that is produced by a particular organism or group of organisms in a given area over a specific period of time. It is often used to measure the productivity of crops, forests, and other ecosystems. Biomass yield can be influenced by a variety of factors, including climate, soil quality, and the genetics of the organisms involved.

II. Half velocity constant :

The half-velocity constant, also known as the Michaelis-Menten constant (Km), is a measure of the substrate concentration at which an enzyme-catalyzed reaction proceeds at half of its maximum velocity. It is an important parameter in enzymology and is used to describe the kinetics of enzymes. The value of Km can provide information about the binding of the substrate to the enzyme and the efficiency of the enzyme-catalyzed reaction.

A low Km value indicates a tight binding of the substrate to the enzyme and a high efficiency of the enzyme-catalyzed reaction, while a high Km value indicates a weaker binding of the substrate to the enzyme and a lower efficiency of the enzyme-catalyzed reaction.

III. Sludge volume index :

The sludge volume index (SVI) is a measure of the settleability of activated sludge, which is the type of sludge produced in the biological treatment of wastewater. It is used to determine the relative amount of suspended solids present in the sludge, and is expressed in milliliters per gram of suspended solids (mL/g).

SVI is calculated by measuring the volume of sludge in milliliters that settles in a graduated cylinder over a period of time, typically 30 minutes, after a specified amount of suspended solids (mg/L) have been added.

A low SVI value indicates good settleability, while a high SVI value indicates poor settleability, which can be caused by factors such as high levels of filamentous microorganisms or changes in the wastewater treatment process.

IV. Maximum substrate utilization rate :

Maximum substrate utilization rate, also known as the maximum specific growth rate or μmax, is the highest rate at which microorganisms can consume a specific substrate. It is the maximal rate of increase in cell numbers or biomass per unit of substrate consumed. μmax is an important parameter in microbial ecology and biotechnology, as it describes the maximum potential growth rate of a microorganism. The value of μmax can be influenced by a variety of factors, including the availability of nutrients, temperature, and the presence of other microorganisms.

It can be used to evaluate the efficiency of microbial processes and the design of bioprocesses such as wastewater treatment, fermentation, and bioremediation.

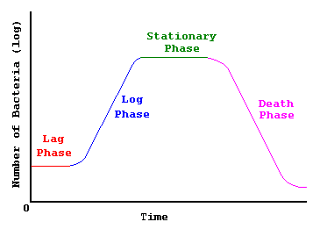

(c) Draw the bacterial growth curve & define each stages in detail.

A bacterial growth curve is a graphical representation of the changes in bacterial population size over time. It typically consists of four stages: lag phase, exponential or log phase, stationary phase, and death phase.

Lag phase: This is the initial stage of bacterial growth, where the bacteria are adapting to their new environment and adjusting to the availability of nutrients. During this phase, there is little to no increase in bacterial population size or biomass.

Exponential or log phase: This is the stage of rapid growth, where the bacterial population size increases exponentially. During this phase, the bacteria are actively growing and reproducing, and the rate of population growth is constant. The exponential growth is represented by a straight line on a semi-log graph.

Stationary phase: This is the stage when the growth rate slows down and the bacterial population size reaches a plateau. The rate of cell growth equals the rate of cell death, and the population size remains constant. This phase is caused by depletion of nutrients, accumulation of toxic metabolic by-products, or inhibition by other microorganisms.

Death phase: This is the final stage of bacterial growth, where the population size begins to decrease due to an increase in cell death. This phase is caused by the depletion of nutrients, the accumulation of toxic metabolic by-products, or the presence of external factors such as antibiotics.

It is worth noting that the shape of the curve can be affected by the type of bacteria, the growth conditions, and the presence of environmental factors. Also, some bacteria may not show all the stages of the curve, or may only show a subset of them.

Or

(c) Write a short note on bio - towers along with its applications.

Bio-towers are a type of wastewater treatment system that utilize a combination of physical, chemical, and biological processes to remove pollutants from wastewater. They consist of a tall, vertical column filled with materials such as gravel, sand, and plastic media that provide a surface for microorganisms to grow on. These microorganisms consume the pollutants in the wastewater as a source of food and energy, breaking down the organic matter and converting it into biomass.

Bio-towers are commonly used for the treatment of industrial wastewater, particularly from food and beverage, chemical, and pharmaceutical industries. They can also be used for treating municipal wastewater and stormwater.

The main advantages of bio-towers include their ability to handle large volumes of wastewater, their high treatment efficiency, and their ability to handle a wide range of pollutants. They are also relatively low-maintenance and can be easily automated. Additionally, they can be used as a polishing step in a multi-stage treatment process to achieve higher levels of treatment.

In summary, bio-towers are a cost-effective and efficient wastewater treatment technology that can be used in various industrial and municipal applications. They utilize microorganisms to break down pollutants and convert them into biomass, resulting in clean and reusable water.

Q.3

(a) Discuss the purposes of the aeration in activated sludge process.

Aeration is a crucial step in the activated sludge process, which is a widely used method for the biological treatment of wastewater. Aeration serves several purposes in this process, including:

Oxygenation: Aeration is used to provide oxygen to the microorganisms present in the activated sludge. These microorganisms, such as bacteria and protozoa, require oxygen to survive and to carry out the biological treatment of the wastewater.

Mixing: Aeration also helps to mix the activated sludge and the wastewater, ensuring that the microorganisms are in contact with the pollutants in the wastewater. This promotes the growth and reproduction of the microorganisms, increasing the efficiency of the treatment process.

Nitrification and denitrification: In addition to oxygenation, aeration also plays a role in the nitrification and denitrification process. Nitrification is the conversion of ammonium (NH4+) to nitrite (NO2-) and then to nitrate (NO3-), which is carried out by Nitrifying bacteria. Denitrification is the conversion of nitrate to nitrogen gas (N2) which is carried out by denitrifying bacteria. Both these processes are important for removing nitrogen compounds from the wastewater.

pH control: Aeration also helps to maintain the pH of the wastewater within the optimal range for the microorganisms. As microorganisms consume the pollutants in the wastewater, the pH of the activated sludge can decrease. Aeration helps to neutralize the acidity and maintain a suitable pH for the microorganisms to survive.

In summary, aeration is a crucial step in the activated sludge process, providing oxygen for microorganisms, promoting mixing, facilitating Nitrification-denitrification and maintaining pH. All these steps help to increase the efficiency of the biological treatment of wastewater, leading to cleaner and reusable water.

(B) Make a list of possible modifications in activated sludge process.

Nutrient addition: Adding nutrients such as nitrogen and phosphorus to the activated sludge can improve the growth and reproduction of the microorganisms, increasing the efficiency of the treatment process.

pH control: Maintaining the pH of the wastewater within the optimal range for the microorganisms can improve the treatment efficiency.

Temperature control: Keeping the temperature of the wastewater within the optimal range for the microorganisms can improve the treatment efficiency.

Air flow rate control: Adjusting the air flow rate in the aeration process can optimize the oxygenation of the microorganisms and improve the treatment efficiency.

Solids retention time (SRT) control: SRT can be adjusted to change the population of microorganisms in the activated sludge, which can improve the treatment efficiency.

Return activated sludge (RAS) rate control: By adjusting the amount of activated sludge that is returned to the aeration tank, the population of microorganisms in the activated sludge can be controlled, which can improve the treatment efficiency.

Anoxic and aerobic phase control: By adjusting the ratio of anoxic and aerobic phase can improve the Nitrification-Denitrification process.

Recycle and Reuse: By recycling the treated water, the water can be reused, also this can help to reduce the amount of sludge produced.

Chemical addition: Addition of chemicals like Alum, Ferric chloride, polyelectrolyte to the wastewater can improve the settling of the sludge, which can improve the treatment efficiency.

These are some of the possible modifications that can be made to the activated sludge process to improve its efficiency. However, the exact modifications that are required will depend on the specific characteristics of the wastewater and the treatment goals.

(C). Draw a neat sketch of UASB reactor and explain its operation in detail.

A UASB reactor (Upflow Anaerobic Sludge Blanket reactor) is a type of anaerobic reactor that is used to treat wastewater. The reactor is typically cylindrical in shape, with a conical bottom and an inclined outlet pipe.

It operates in three main zones:

Inlet zone : The wastewater enters the reactor through the inlet pipe, which is located at the top of the reactor. The wastewater is distributed evenly throughout the reactor by a distributor plate.

Anaerobic zone: The wastewater then flows downwards through the reactor, where it is treated by anaerobic microorganisms present in the sludge blanket. The microorganisms consume the organic matter present in the wastewater, converting it into biogas (methane and carbon dioxide) and a small amount of solids.

Outlet zone: The treated wastewater, now called effluent, exits the reactor through the outlet pipe which is located at the bottom of the reactor. The effluent is relatively clear, with low levels of pollutants, and can be discharged or used for further treatment.

The UASB reactor is unique in its ability to separate the biomass from the liquid and also it's ability to maintain a high concentration of microorganisms in the reactor. The microorganisms form a dense, granular sludge that can be easily separated from the treated wastewater, which makes it a cost-effective solution for treating wastewater.

The UASB reactor is particularly useful for treating wastewater with high organic content, such as wastewater from food processing, breweries, and other industrial processes. It can also be used in conjunction with other treatment methods, such as aerobic treatment, to achieve higher levels of treatment.

Or

(A) Write down the terminology used in 3. BOD remaining

1. BOD Test Ultimate BOD

BOD (Biochemical Oxygen Demand) test is a measure of the amount of oxygen consumed by microorganisms as they break down organic matter in a sample of water or wastewater. It is used to determine the level of pollution in water bodies, and to design and evaluate the performance of wastewater treatment systems. The BOD test is usually carried out over a period of 5 days at 20°C.

The ultimate BOD (UBOD) is the theoretical oxygen demand of the organic matter present in the sample, assuming complete oxidation of all organic compounds, including those that are resistant to biological degradation. It is a theoretical value, and is not directly measurable, but it can be estimated by measuring the BOD of the sample over a longer period of time, such as 20-30 days. The UBOD can be used to determine the theoretical maximum efficiency of a wastewater treatment system, and to evaluate the potential for further treatment.

It is important to note that the BOD test is just one of the methods used to evaluate the water quality and wastewater treatment efficiency, other parameters like COD (Chemical Oxygen Demand), TSS (Total Suspended Solids), TDS (Total dissolved Solids) and pH are also used for the same.

2. BOD Exerted :

The BOD exerted is the amount of oxygen consumed by microorganisms as they break down organic matter in a sample of water or wastewater over a specific period of time. It is a measure of the pollution level of the water and can be used to evaluate the efficiency of a wastewater treatment system. BOD exerted is typically measured over a 5-day period at 20°C, and is reported as mg/L of oxygen consumed.

The BOD exerted is the actual oxygen demand of the organic matter present in the sample, as opposed to the Ultimate BOD (UBOD) which is the theoretical oxygen demand of the organic matter present in the sample. The BOD exerted is directly measurable, whereas the UBOD is not directly measurable and is estimated by measuring BOD over a longer period of time.

It is used as a measure of water quality, because it reflects the amount of oxygen that will be depleted from a water body if the organic matter present in the water is left untreated.

3. BOD Remaining

The BOD remaining (also known as residual BOD or BOD5) is the amount of oxygen remaining in a sample of water or wastewater after a specific period of time, usually 5 days, at a specific temperature, usually 20°C, following the BOD test. It is determined by measuring the initial dissolved oxygen (DO) level of the sample and then measuring the final DO level after the 5-day incubation period. The difference between the initial and final DO levels is the BOD remaining.

It is usually calculated as the difference between the initial BOD (BODi) and the BOD exerted. BOD remaining = BODi- BOD exerted.

BOD remaining is an important parameter in evaluating the efficiency of wastewater treatment plants, as it reflects the amount of organic matter that has not been broken down by the microorganisms present in the treatment process. A low BOD remaining value indicates that the treatment process is working efficiently, while a high BOD remaining value may indicate that the treatment process is not working effectively and more optimization is required.

It's worth noting that, the BOD remaining is not a direct measure of water quality, but it provides an insight on the efficiency of the treatment system.

(B) Compare fine bubble & coarse bubble aeration system.

Fine bubble aeration and coarse bubble aeration are two different types of aeration systems used in wastewater treatment processes.

Fine bubble aeration systems use small bubbles that are typically less than 2mm in diameter. These bubbles are generated by fine bubble diffusers, which are typically made of plastic or ceramic materials. Fine bubble aeration systems are known for their high oxygen transfer efficiency, as the small bubbles have a large surface area-to-volume ratio and can dissolve more oxygen into the water. They are also relatively low-maintenance, as they have fewer moving parts and are less prone to clogging. However, they are generally more expensive than coarse bubble systems.

Coarse bubble aeration systems use large bubbles that are typically greater than 2mm in diameter. These bubbles are generated by coarse bubble diffusers, which are typically made of rubber or plastic materials. Coarse bubble aeration systems are known for their low capital cost and ease of maintenance, as the large bubbles have a small surface area-to-volume ratio, and are less prone to clogging. However, they have a lower oxygen transfer efficiency as compared to fine bubble systems, and are not as effective in dissolving oxygen into the water.

In summary, fine bubble aeration systems are more efficient in oxygen transfer, but are more expensive and require more maintenance, while coarse bubble aeration systems are less efficient in oxygen transfer, but are cheaper and require less maintenance. The choice of system will depend on the specific requirements of the wastewater treatment process and the available budget.

(C) Draw a neat sketch of activated sludge process & explain the process in detail.

The activated sludge process is a widely used method for the biological treatment of wastewater. It involves the use of microorganisms, such as bacteria and protozoa, to remove pollutants from wastewater. The process typically consists of three main components: an aeration tank, a clarifier, and a sludge return system.

Aeration tank: The aeration tank is where the microorganisms are added to the wastewater. The tank is typically rectangular or circular in shape, and is equipped with mechanical aerators or diffusers that provide oxygen to the microorganisms. The microorganisms consume the pollutants in the wastewater as a source of food and energy, breaking down the organic matter and converting it into biomass.

Clarifier: The clarifier is where the microorganisms and the treated wastewater are separated. The treated wastewater exits the clarifier as relatively clear effluent, while the microorganisms form a dense, granular sludge that is returned to the aeration tank.

Sludge Return System: The sludge return system is used to transport the sludge from the clarifier back to the aeration tank. The sludge is typically pumped back to the aeration tank, where it is mixed with the incoming wastewater. This helps to maintain a high population of microorganisms.

Q.4

(a) Write down merits & demerits of anaerobic treatment technology over.

Anaerobic treatment technology is a method of wastewater treatment that uses microorganisms to break down organic matter in the absence of oxygen. Here are some of the merits and demerits of anaerobic treatment technology:

Merits:

Energy recovery: Anaerobic treatment can generate biogas, which is a mixture of methane and carbon dioxide, as a by-product. Biogas can be used as a source of energy, either by burning it to produce heat or by using it to generate electricity.

Reduced sludge production: Anaerobic treatment typically produces less sludge than aerobic treatment, which can lead to lower disposal costs and lower land requirements.

Reduced odors: Anaerobic treatment produces less odorous compounds than aerobic treatment, which can lead to a reduction in odors.

Lower Energy Requirements: Anaerobic treatment typically requires less energy than aerobic treatment, as the microorganisms do not require oxygen.

Demerits:

Lower Treatment Efficiency: In general, anaerobic treatment is not as effective as aerobic treatment in breaking down certain types of pollutants, such as nitrogen and phosphorus.

Longer Treatment Time: Anaerobic treatment typically takes longer than aerobic treatment, as the microorganisms work at a slower rate.

pH control: Anaerobic treatment requires strict pH control, as the microorganisms are sensitive to changes in pH.

Temperature control: Anaerobic treatment requires strict temperature control, as the microorganisms are sensitive to changes in temperature.

Limited application: Anaerobic treatment is not suitable for the treatment of high strength industrial wastewater and it is not suitable for the treatment of wastewater with high salt content, heavy metals and toxic pollutants.

In summary, anaerobic treatment technology has the benefits.

(b) Explain the Difference between oxidation ditch & oxidation pond.

Oxidation ditch and oxidation pond are two different types of aerobic wastewater treatment systems. Both systems use microorganisms to break down pollutants in the wastewater, but they differ in their design and operation.

An oxidation ditch is a circular or oval-shaped channel that is used to treat wastewater. The channel is typically lined with concrete or other materials to prevent leakage. Wastewater is continuously fed into the channel, and is mixed with air by mechanical aerators or diffusers. The microorganisms present in the wastewater consume the pollutants, breaking down the organic matter and converting it into biomass. The treated wastewater is then discharged from the channel, while the biomass is removed and returned to the channel to maintain a high population of microorganisms.

An oxidation pond, also known as a stabilization pond or an aerated lagoon, is a large pond or lagoon used to treat wastewater. The pond is typically lined with clay or other materials to prevent leakage. Wastewater is fed into the pond, and is mixed with air by natural processes such as wind and solar radiation. The microorganisms present in the wastewater consume the pollutants, breaking down the organic matter and converting it into biomass. The treated wastewater is then discharged from the pond, while the biomass is removed and returned to the pond to maintain a high population of microorganisms.

In summary, the main difference between oxidation ditch and oxidation pond is the way they mix the wastewater with air. Oxidation ditch uses mechanical aerators or diffusers to mix the wastewater with air, while oxidation pond uses natural processes like wind and solar radiation to mix the wastewater with air. Also, oxidation ditch is circular or oval-shaped channel, while oxidation pond is a large pond or lagoon.

(c) Explain Anaerobic process as a four sequential steps treatment technology along with Environmental factors affecting anaerobic process.

Anaerobic treatment technology is a method of wastewater treatment that uses microorganisms to break down organic matter in the absence of oxygen. The anaerobic process typically involves four sequential steps: hydrolysis, acidogenesis, acetogenesis, and methanogenesis.

Hydrolysis: In the first step, complex organic compounds are broken down into simpler compounds by enzymes secreted by the microorganisms. This step is called hydrolysis.

Acidogenesis: In the second step, the simple compounds produced in the hydrolysis step are further broken down by acidogenic bacteria into volatile fatty acids (VFAs) and other products.

Acetogenesis: In the third step, the VFAs and other products produced in the acidogenesis step are converted by acetogenic bacteria into acetate, carbon dioxide, and hydrogen gas.

Methanogenesis: In the fourth step, the acetate and other products produced in the acetogenesis step are converted by methanogenic bacteria into methane and carbon dioxide. This methane can be captured and used as a source of energy.

Environmental factors that affect the anaerobic process include:

Temperature: the microorganisms used in anaerobic treatment are sensitive to changes in temperature, and optimal temperature range is typically between 35°C to 38°C.

pH: the microorganisms used in anaerobic treatment are sensitive to changes in pH, and the pH range should be maintained between 6.5 and 7.5.

Solids Retention Time (SRT): The SRT should be maintained at a specific level to maintain.

OR

(a) Explain the "Bio sloughing" phenomena of trickling filter.

Bio-sloughing is a phenomenon that can occur in trickling filters, which are a type of fixed-film wastewater treatment system. It is the detachment and washing away of the microbial biomass from the filter media.

Trickling filters are composed of a bed of coarse media, such as rocks, gravel or plastic, on which a film of microorganisms grows. The microorganisms use the organic matter in the wastewater as a food source and convert it into biomass. As the microorganisms grow and reproduce, the biomass builds up on the filter media. When the biomass becomes too thick, it can detach from the media and wash away, a process known as bio-sloughing.

The bio-sloughing can occur due to a number of factors, such as:

- High organic loading, which can cause the microorganisms to grow too quickly and exhaust the available oxygen

- High flow rates, which can cause erosion and scouring of the media

- High solids content, which can clog the filter and cause the media to become saturated

- Changes in the characteristics of the wastewater, such as pH or temperature

- Inadequate maintenance, such as failure to clean the filter media regularly.

(b) Explain with neat sketch subsurface flow system.

A subsurface flow system is a type of constructed wetland used for the treatment of wastewater. It consists of a shallow pond or basin filled with gravel, sand, or other porous media that serves as a growing medium for aquatic plants and microorganisms.

The wastewater is fed into the pond or basin, where it flows horizontally through the gravel or sand medium, providing a large surface area for the microorganisms to grow on. The microorganisms use the organic matter in the wastewater as a food source and convert it into biomass, while the plants help to remove pollutants and provide oxygen to the microorganisms.

The subsurface flow system is typically divided into two main zones: the treatment zone, where the microorganisms and plants remove pollutants from the wastewater, and the discharge zone, where the treated wastewater is discharged.

The subsurface flow system can be designed in a variety of ways, depending on the specific requirements of the wastewater treatment process. For example, it can be designed as a single-pass or multi-pass system, with different types of media and plants.

subsurface flow system as a constructed wetland with a pond or basin filled with gravel, sand, or other porous media, where the wastewater flows horizontally through the medium providing a large surface area for the microorganisms to grow on, while the plants help to remove pollutants and provide oxygen to the microorganisms.

(c) Determine the volume in liters of methane gas generated per kg COD consumed at STP.

The volume of methane gas generated per kg COD consumed at STP (Standard Temperature and Pressure) can be determined using the stoichiometry of the anaerobic digestion process. The stoichiometry of anaerobic digestion is the ratio of the mass of the substrate consumed to the mass of the products produced.

The stoichiometry of anaerobic digestion of organic matter is typically represented as COD (Chemical Oxygen Demand) consumed to methane produced. The stoichiometry for the anaerobic digestion process can be represented as:

COD consumed (mg/L) = methane produced (mL/g)

The volume of methane produced at STP is calculated using the ideal gas law, PV = nRT, where P is the pressure, V is the volume, n is the number of moles, R is the gas constant, and T is the temperature.

At STP, the temperature is 0°C and the pressure is 1 atm. So, the volume of methane produced at STP would be 22.4 L/mol.

If we take an example, If we consume 200 mg/L of COD, we would produce 200/0.35 = 571.43 mL/g of methane at STP.

It's important to note that this is a theoretical value, and the actual volume of methane produced in an anaerobic digestion process may vary depending on a number of factors such as the type and strength of the substrate, the pH and temperature of the system, and the presence of inhibitory compounds.

(a) Define reaction rates & explain first & second order types of reaction rates.

Reaction rates refer to the speed at which a chemical reaction takes place. They can be measured by the change in the concentration of a reactant or product over time.

First order reactions have a reaction rate that is directly proportional to the concentration of only one reactant. The rate equation for a first order reaction is typically written as: rate = k[A], where k is the rate constant and [A] is the concentration of reactant A.

Second order reactions have a reaction rate that is directly proportional to the concentrations of two reactants. The rate equation for a second order reaction is typically written as: rate = k[A][B], where k is the rate constant and [A] and [B] are the concentrations of reactants A and B.

(B) Briefly explain on overland flow treatment system.

An overland flow treatment system is a type of stormwater management system that uses vegetation and soil to filter and treat runoff from impervious surfaces such as roads, parking lots, and buildings. It works by directing stormwater runoff over natural or constructed surfaces, where it is slowly released, filtered, and treated by a combination of physical, chemical, and biological processes.

The main components of an overland flow treatment system are the catchment area, the conveyance system, and the treatment area. The catchment area is the area where stormwater runoff is collected, the conveyance system is the network of channels, pipes, or swales that directs the runoff to the treatment area, and the treatment area is the area where the runoff is filtered and treated.

The treatment area typically consists of a series of landscaped terraces, swales or bioretention basins that are designed to slow down and detain the runoff. These features are typically planted with vegetation such as grasses, shrubs, or trees that help to filter the runoff and promote infiltration into the soil. The soil itself also plays a key role in the treatment process, as it acts as a filter and a source of nutrients for the plants.

Overland flow treatment systems are considered to be a best management practice for stormwater management and are becoming increasingly popular due to their ability to improve water quality, reduce flooding, and provide a host of other environmental benefits.

(C) Write down the mass balance for CFSTR with recycle and hence Derive the equation for finding bio kinetic constant.

The mass balance for a continuously stirred tank reactor (CFSTR) with recycle can be expressed as:

F(V_0 + V_R) = F_0 + F_R + V_R*dX/dt

Where:

- F is the flow rate (volume/time) of the liquid in the reactor

- V_0 is the volume of the reactor

- V_R is the volume of the recycle stream

- F_0 is the flow rate of the fresh feed stream

- F_R is the flow rate of the recycle stream

- X is the concentration of the reactant or product in the reactor

- dX/dt is the rate of change of X with respect to time

To derive the equation for finding the kinetic constant, we can assume that the rate of the reaction is first order with respect to the reactant concentration, X.

-dX/dt = k*X

where k is the first-order kinetic constant.

By substituting this into the mass balance equation, we can isolate k:

k = (F_0 + F_R - F(V_0 + V_R)) / (V_R*X)

This equation can be used to determine the kinetic constant, k, of the reaction, given measurements of the flow rates and concentrations of the streams, as well as the volume of the reactor and the recycle stream.

Q.5

(a) Explain with neat sketch subsurface flow system.

A subsurface flow system, also known as a subsurface flow constructed wetland or subsurface flow constructed treatment wetland (SFCW), is a type of constructed wetland used for wastewater treatment. It is designed to mimic the natural process of wetland filtration by allowing wastewater to flow through a subsurface media, such as gravel or sand, to remove pollutants.

A typical subsurface flow system consists of the following main components:

Inlet structure: This is where the wastewater enters the system. It is designed to distribute the wastewater evenly across the width of the wetland.

Subsurface media: This is the layer of gravel or sand through which the wastewater flows. The media provides a large surface area for the growth of microorganisms that break down the pollutants in the wastewater.

Outlet structure: This is where the treated wastewater exits the system. It is designed to remove any solids that may have accumulated in the wetland.

Vegetation: Plants are typically grown on the surface of the wetland. They not only provide aesthetic value but also play a role in the treatment process by uptake of nutrients and providing shade to the microorganisms present in the subsurface.

Liner: A liner is often used to prevent the infiltration of the treated water into the ground water.

A Schematic of Subsurface flow system:

As seen in the diagram, wastewater enters the system through the inlet structure and flows through the subsurface media, where it is treated by microorganisms and plants. The treated wastewater then exits the system through the outlet structure.

(B) Name the types of reactors & explain any one type with neat sketch.

There are several types of reactors used in chemical and biological processes, including:

Batch Reactors: A batch reactor is a type of reactor in which all of the reactants are added at the beginning of the reaction and the entire reaction takes place in a single, sealed vessel. A batch reactor is not continuously fed reactants, but instead the entire reaction is completed within the reactor.

Continuous Stirred Tank Reactors (CSTR): A CSTR is a type of reactor in which reactants are continuously fed into the reactor and the reaction is carried out by stirring the contents of the reactor to ensure good mixing. The product is continuously removed from the reactor at the same rate as the reactants are fed in.

Plug Flow Reactors (PFR): A PFR is a type of reactor in which the reactants are fed into one end of the reactor and the products are removed from the other end. The reactants are assumed to move through the reactor in plug flow, meaning that the reactants at the front of the reactor are not mixed with the reactants at the back of the reactor.

Tubular Flow Reactors: In a tubular flow reactor the reactants flow in a tube and the reaction takes place within the tube. The tube is usually packed with catalyst.

Fixed Bed Reactors: A fixed bed reactor is a type of reactor in which a bed of solid catalyst is used to catalyze the reaction. The reactants are passed through the bed of catalyst, and the products are removed from the other end.

Fluidized Bed Reactors: A fluidized bed reactor is a type of reactor in which a bed of solid particles is maintained in a fluid-like state by passing a gas through the bed. This allows the particles to move freely and mix easily, which can be useful for reactions that require good mixing or for reactions that take place on the surface of the particles.

For example, we will discuss Continuous Stirred Tank Reactors (CSTR):

A Continuous Stirred Tank Reactor (CSTR) is a type of reactor in which reactants are continuously fed into the reactor and the reaction is carried out by stirring the contents of the reactor to ensure good mixing. The product is continuously removed from the reactor at the same rate as the reactants are fed in.

As seen in the diagram, the reactants are fed into the reactor through an inlet and are continuously stirred by a mechanical agitator. The products are continuously removed from the reactor through an outlet. The reactor is assumed to be perfectly mixed, meaning that the concentration of reactants and products is the same at every point in the reactor at all times.

(C) Explain working of Rotating Biological contactor with the help of a neat sketch.

A Rotating Biological Contactor (RBC) is a type of wastewater treatment system that uses a rotating biological surface, such as a disk or drum, to provide a large surface area for the growth of microorganisms that break down the pollutants in the wastewater. The RBC system is typically used in combination with a primary treatment system, such as a sedimentation tank, to provide secondary treatment of the wastewater.

The RBC system consists of the following main components:

Rotating biological surface: This is the surface on which the microorganisms grow. It is typically a disk or drum that is rotated slowly to ensure that the microorganisms are evenly distributed across the surface.

Water distribution system: This is used to distribute the wastewater evenly across the rotating biological surface.

Water collection system: This is used to collect the treated wastewater from the RBC system.

Drive mechanism: This is used to rotate the rotating biological surface.

As seen in the diagram, the wastewater is first passed through a primary treatment system, such as a sedimentation tank, to remove large particles. The treated wastewater is then fed onto the rotating biological surface, where microorganisms break down the pollutants. The rotating biological surface is slowly rotated to ensure that the microorganisms are evenly distributed across the surface. The treated wastewater is collected by the water collection system, and the microorganisms are scraped off the rotating biological surface by a scraper mechanism.

The microorganisms that are scraped off the rotating biological surface are known as the mixed liquor suspended solids (MLSS) and are returned back to the inlet of the reactor for further treatment. This ensures that the microorganisms are continuously present in the reactor to treat the incoming wastewater. This process is known as the biological treatment process and it typically remove 80-90% of the organic matter present in the wastewater.

.jpg)

0 Comments