- Paper solved by : Om Sonawane

- Subject Code: 3161304

- Date:13-12-2022

Q.1

(a) Define: Anoxic process, HRT and SRT

Anoxic process : Refers to a process in which the oxygen levels in a system, such as a body of water or a wastewater treatment plant, are reduced or depleted.

HRT (Hydraulic Retention Time) : is a measure of how long water stays in a treatment system. It is typically used in wastewater treatment plants to determine the appropriate size of the treatment facility.

SRT (Sludge Retention Time) : is a measure of how long sludge (semi-solid waste) stays in a treatment system. It is typically used in wastewater treatment plants to determine the appropriate size of the treatment facility and the rate of sludge production.

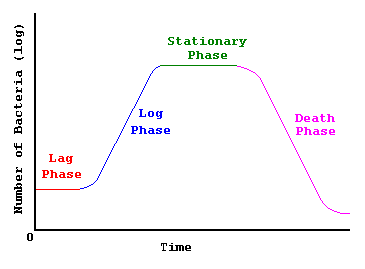

Draw a neat figure of bacterial growth phases curve and explain any two phases.

Lag phase: During this phase, the number of bacteria remains relatively constant as the bacteria adjust to their new environment and begin to reproduce.

Log (exponential) phase: During this phase, the number of bacteria increases rapidly as the bacteria reproduce at their maximum rate. This is often considered the "ideal" phase for bacterial growth as it is when the population is growing most quickly.

Stationary phase: During this phase, the number of bacteria in the population stops increasing and levels off. This is due to the fact that the bacteria have consumed all of the available nutrients or have reached the carrying capacity of the environment.

Death phase: During this phase, the number of bacteria in the population begins to decrease as the bacteria begin to die off. This is due to the depletion of nutrients, the accumulation of waste products, or the presence of toxins in the environment.

It's worth to mention that not all the bacterial population will go through all the phase, it depends on the specific conditions of the environment.

(C) Differentiate between aerobic and anaerobic process of wastewater treatment.

Aerobic and anaerobic are two different types of processes used in wastewater treatment.

Aerobic treatment is a process that uses oxygen to break down organic matter in wastewater. This is typically done using microorganisms that consume the organic matter and convert it into carbon dioxide and water. Aerobic treatment is often used in the early stages of wastewater treatment, as it can remove a large portion of the organic matter. Aerobic treatment can be done using a variety of methods, including activated sludge, trickling filters, and rotating biological contactors.

Anaerobic treatment is a process that occurs without oxygen. Instead, anaerobic microorganisms are used to break down organic matter in wastewater. These microorganisms produce methane, carbon dioxide, and other gases as a byproduct of their metabolism. Anaerobic treatment is often used in the later stages of wastewater treatment, after the majority of the organic matter has been removed. Anaerobic treatment can be done using a variety of methods, including anaerobic lagoons, anaerobic digesters, and upflow anaerobic sludge blanket reactors.

Aerobic treatment is often considered more efficient than anaerobic treatment, as it can remove more organic matter from the wastewater. However, anaerobic treatment has the added benefit of producing methane, which can be used as a source of energy.

Q.2

(a) Explain The role of microorganism in wastewater treatment

Microorganisms play a crucial role in the treatment of wastewater. They are responsible for breaking down the organic matter present in wastewater, converting it into simpler compounds that can be further treated or safely released into the environment.

In aerobic treatment processes, microorganisms consume the organic matter in the wastewater, using oxygen as an electron acceptor. The microorganisms convert the organic matter into carbon dioxide and water, which can be safely released into the environment. Aerobic treatment processes can be done using a variety of methods, including activated sludge, trickling filters, and rotating biological contactors.

In anaerobic treatment processes, microorganisms consume the organic matter in the wastewater, but in the absence of oxygen. Instead, they use other electron acceptors such as sulfur, nitrate, or carbon dioxide. The microorganisms convert the organic matter into methane, carbon dioxide, and other gases. These gases can be captured and used as a source of energy. Anaerobic treatment processes can be done using a variety of methods, including anaerobic lagoons, anaerobic digesters, and upflow anaerobic sludge blanket reactors.

In addition to breaking down organic matter, microorganisms also play a role in the removal of other pollutants in wastewater such as nitrogen and phosphorus compounds. They play a key role in the Nitrification-Denitrification Process (N-D Process) where they convert ammonia to nitrite and then to nitrate, and then the final step is to convert it back to nitrogen gas by denitrifying bacteria.

Overall, the role of microorganisms in wastewater treatment is to break down the organic matter and other pollutants in the wastewater, making it safe to release into the environment and also produce biogas.

(b) Give the difference between Coarse bubble and fine bubble diffused aeration.

Coarse bubble diffused aeration uses larger bubbles to aerate a liquid, while fine bubble diffused aeration uses smaller bubbles. The main difference between the two is the size of the bubbles they produce. Coarse bubble diffusers typically have a lower oxygen transfer efficiency than fine bubble diffusers, but they are less prone to clogging and are less expensive. Fine bubble diffusers have a higher oxygen transfer efficiency, but they are more prone to clogging and are more expensive.

(C) The 5-day BOD of a wastewater is 210mg/l at 200C. What will be the ultimate BOD and 10-day BOD? If the sample has been incubated at 300C what would the 5-day BOD have been. (k at 200C = 0.-1)

The ultimate BOD, also known as the ultimate biochemical oxygen demand, is the theoretical oxygen demand of a wastewater sample after an infinite amount of time. It can be calculated by multiplying the 5-day BOD by the ultimate biodegradability ratio (k) at the given temperature.

At 200C, the ultimate BOD is: 210 mg/l x (1/0.1) = 2100 mg/l

The 10-day BOD can be calculated using the same method:

10-day BOD = 210 mg/l x (1/0.1)^(10/5) = 441 mg/l

It's important to note that this is an estimation based on the assumption that the rate of oxygen uptake is constant over the 10-day period.

If the sample had been incubated at 300C, the 5-day BOD would have been lower than 210mg/l, because the k value at 300C is generally lower than at 200C, meaning the rate of oxygen uptake would have been slower and the sample would have taken longer to reach a BOD of 210mg/l.

Or

(C) BOD result of sewage at 370C are

t, day 0 1 2 3 4 5

y, mg/l 0 60 108 151 182 201

Determine the values of rate constant and ultimate BOD using least square

method.

Q.3

(a) Why incubation period is fixed for 5 days at 20 °C in BOD test as per the Standard method.

The incubation period of 5 days at 20 °C for the Biochemical Oxygen Demand (BOD) test is used as a standard method because it is a temperature at which the majority of bacteria found in most natural waters will be active. At this temperature, the bacteria will consume the organic material in the water sample, causing a decrease in the oxygen levels.

This decrease in oxygen levels is used as an indicator of the amount of organic matter present in the water. The incubation period of 5 days is the time required for the bacteria to consume enough of the organic matter to produce a measurable decrease in oxygen levels. This standard method is widely used because it is easy to perform, simple to understand and provides a consistent way to measure BOD.

(B) Draw a neat sketch of Constructed wet lands system and explain in brief.

.jpeg)

A Constructed Wetlands System is a man-made treatment system that uses natural processes to treat wastewater. The system typically consists of a series of shallow ponds or channels that are filled with water and planted with wetland plants. The wastewater is fed into the first pond, where it is treated by a combination of physical, chemical, and biological processes.

The physical process of sedimentation occurs in the first pond, where the heavier particles in the wastewater settle to the bottom. The chemical process of oxidation occurs as the wastewater is exposed to the sun and air, which helps to break down the organic matter. The biological process of decomposition occurs as the wetland plants and microorganisms in the water consume the organic matter. The treated water then flows into the next pond, where the process is repeated, and so on.

Constructed wetlands are highly effective in removing pollutants such as nutrients, suspended solids, and bacteria from wastewater. They also provide many other benefits, including wildlife habitat, recreation, and aesthetic value. They are relatively low-cost and easy to maintain, making them an attractive option for small communities and rural areas that may not have access to more expensive wastewater treatment technologies.

(C) Prepare mass balance for CFSTR with recycle for biomass & hence derive the equation to find volume of tank.

A continuous flow stirred tank reactor (CFSTR) is a type of reactor that is used to treat wastewater or other liquid streams. A CFSTR with recycle for biomass can be modeled using mass balance equations.

The mass balance equation for the biomass in the reactor can be written as:

dX/dt = (F_in * X_in - F_out * X_out) + (r_X * V)

Where:

- dX/dt is the change in biomass concentration over time

- F_in is the flow rate of the influent (wastewater) into the reactor

- X_in is the biomass concentration in the influent

- F_out is the flow rate of the effluent (treated water) out of the reactor

- X_out is the biomass concentration in the effluent

- r_X is the specific growth rate of the biomass

- V is the volume of the reactor

The mass balance equation for the substrate (organic matter) in the reactor can be written as:

dS/dt = (-r_X * S * X) + (F_in * S_in - F_out * S_out)

Where:

- dS/dt is the change in substrate concentration over time

- S is the substrate concentration in the reactor

- S_in is the substrate concentration in the influent

- S_out is the substrate concentration in the effluent

To find the volume of the reactor, we need to combine the above two equations and solve for V.

First we can assume that the biomass and substrate are being consumed at the same rate, so r_X * S * X = r_X * X * S = r_X * X_in * S_in

Then we can substitute this into the second equation:

dS/dt = (-r_X * X_in * S_in) + (F_in * S_in - F_out * S_out)

We can also substitute the biomass equation into the substrate equation:

dS/dt = (-r_X * X_in * S_in) + (F_in * S_in - F_out * S_out)

dS/dt = (-r_X * X_in * S_in) + (F_in * S_in - F_out * S_out) + (r_X * V)

By solving this equation for V we get:

V = (dS/dt + (F_in * S_in - F_out * S_out)) / r_X

This equation can be used to find the volume of the reactor when given the appropriate input data. It is important to note that this is a simplified model and it can be affected by other factors such as, microorganisms death and inactivation, pH, temperature and other environmental conditions.

Q.3

(a) Draw a neat sketch of Overland flow system and explain wastewater distribution method in same.

An overland flow system is a type of constructed wetland that is used to treat wastewater. The system consists of a graded surface, usually a grassy or vegetated area, through which the wastewater flows. The wastewater is distributed over the surface of the area through a series of channels, ditches, or pipes.

The wastewater distribution method used in an overland flow system can vary depending on the specific design of the system. Some common methods include:

Surface flow: The wastewater is distributed over the surface of the area through a series of channels, ditches, or pipes. The water flows over the surface of the vegetation, where it is treated by physical, chemical, and biological processes.

Subsurface flow: The wastewater is distributed under the surface of the area through a series of pipes or trenches. The water flows through the soil and is treated by physical, chemical, and biological processes.

Hybrid flow: A combination of surface flow and subsurface flow. The wastewater is distributed over the surface of the area and through a series of pipes or trenches.

Infiltration flow : The wastewater is distributed over the surface and then it is allowed to seep into the soil, where it is treated by physical, chemical, and biological processes.

Overland flow systems are effective in removing pollutants such as nutrients, suspended solids, and bacteria from wastewater. They are also relatively low-cost and easy to maintain, making them an attractive option for small communities and rural areas that may not have access to more expensive wastewater treatment technologies.

It is important to note that the design of the system and the wastewater distribution method used will depend on the specific needs of the site and the characteristics of the wastewater being treated.

(B) Describe in brief the operating problems involved with following:

(i) Trickling Filter :

A trickling filter is a type of wastewater treatment system that uses a bed of rocks or plastic media to support a population of microorganisms that break down organic matter in the wastewater. There are several operating problems that can occur with trickling filters, including:

Clogging: The filter media can become clogged with debris, reducing the surface area available for bacterial growth and decreasing the filter's efficiency.

Odor: If the filter is not operated properly, anaerobic conditions can develop, leading to the production of foul-smelling gases.

Excessive Biomass: If the filter is overloaded with organic matter, the microorganisms can become overloaded, leading to the production of excess biomass that must be removed.

pH changes: The pH of the wastewater can affect the activity of the microorganisms and should be monitored and adjusted as needed.

Choking: Blockages in the inlet or outlet pipes can reduce the flow of wastewater through the filter and lead to poor treatment performance.

Overall, proper design and operation of trickling filters is essential for ensuring efficient, effective wastewater treatment.

(ii) Rotating Biological Contactor :

A rotating biological contactor (RBC) is a type of wastewater treatment system that uses a rotating drum with a biofilm growing on its surface to remove pollutants from the wastewater. There are several operating problems that can occur with RBCs, including:

Fouling: The biofilm can become fouled with debris, reducing the surface area available for bacterial growth and decreasing the RBC's efficiency.

Biomass washout: The RBC drum can rotate too fast, leading to the washing out of the biofilm and poor treatment performance.

Blockages: Blockages in the inlet or outlet pipes can reduce the flow of wastewater through the RBC and lead to poor treatment performance.

pH changes: The pH of the wastewater can affect the activity of the microorganisms and should be monitored and adjusted as needed.

Mechanical failure: RBCs are mechanical devices, and as such, they can suffer from wear and tear, or breakdowns that can lead to loss of treatment performance

Overall, proper design and operation of RBCs is essential for ensuring efficient, effective wastewater treatment. It is important to regularly maintain and inspect the equipment to minimize downtime and ensure optimal performance.

Q.4

(a) Explain the terms:

(i) F/M Ratio : The F/M ratio is a term used to describe the proportion of females to males in a population. It is typically expressed as a ratio, such as 2:1 or 3:2, or as a percentage, such as 60% females and 40% males. This ratio can be used to describe the gender distribution in a specific group or population, such as a school, workplace, or country. Understanding the F/M ratio can be useful in fields such as sociology, demography, and biology, as it can provide insight into the dynamics of a population and potential gender-based disparities or inequalities.

(ii) MCRT/SRT : MCRT (Mean Chromatic Ray Time) and SRT (Spatial Resolution Time) are two different concepts related to image and video processing.

MCRT is a measurement of the time it takes for a pixel to change from one color to another. It is commonly used to evaluate the performance of displays, such as computer monitors or televisions, and is typically measured in milliseconds (ms). A lower MCRT value indicates a faster color transition time and a more responsive display.

SRT (Spatial Resolution Time) is a measure of the time it takes for an image to be fully resolved. It is commonly used to evaluate image-capture devices, such as cameras and scanners, and is typically measured in seconds. A lower SRT value indicates that the image is resolved more quickly and the device is more efficient.

In summary, MCRT is related to the color transition time of a display, SRT is related to the time it takes for an image to be fully resolved in an image capture device.

(iii) Specific Growth Rate

The specific growth rate (SGR) is a measure of the rate at which a population of microorganisms, such as bacteria or yeast, increases in size over a given period of time. It is usually expressed as a percentage and is calculated by dividing the increase in biomass by the initial biomass and then multiplying by 100. The specific growth rate can be used to monitor the growth of a culture and to optimize conditions for growth, such as temperature and nutrient levels.

(B) Explain the procedure for determination of kinetic constant for BOD in laboratory.

The procedure for determining the kinetic constant (also known as the "microbial decay coefficient") for biological oxygen demand (BOD) in a laboratory typically involves the following steps:

- Inoculate a culture of microorganisms into a BOD bottle containing a known volume of a sample of water or wastewater. The inoculum should be prepared in such a way that the population of microorganisms is in the logarithmic phase of growth.

- Seal the BOD bottle and incubate it at a temperature of 20-25°C for a period of five days.

- Measure the dissolved oxygen (DO) concentration in the BOD bottle at the beginning of the incubation period and at the end of the five-day period.

- Calculate the BOD value for the sample by subtracting the final DO concentration from the initial DO concentration.

- Plot the BOD values against time and fit a straight line to the data using linear regression. The slope of the line is the kinetic constant (k) for the sample.

- Repeat the procedure with multiple samples to obtain a mean value for k.

It is important to note that the BOD test must be conducted in the dark and at 20°C-25°C as the oxygen demand and rate of substrate utilization is temperature dependent. Also, the test should be conducted for a period of 5 days as the oxygen demand by microorganisms is not instantaneous and takes time to manifest.

(C) Enlist an explain the fundamental requirements of natural treatment systems.

The fundamental requirements of natural treatment systems are:

Sufficient area: Natural treatment systems require a sufficient area to accommodate the treatment processes, such as infiltration, evapotranspiration, and filtration.

Adequate infiltration: Natural treatment systems rely on infiltration to allow water to percolate through the soil and be treated by physical, chemical, and biological processes.

Adequate vegetation: Natural treatment systems rely on vegetation, such as trees and grasses, to provide shade, absorb pollutants, and improve water quality through evapotranspiration.

Adequate microorganisms: Natural treatment systems rely on microorganisms to break down pollutants in the water and soil.

Adequate oxygen: Natural treatment systems require oxygen to support the growth and activity of microorganisms.

Adequate pH: Natural treatment systems require a neutral pH level to support the growth and activity of microorganisms and vegetation.

Adequate drainage: Natural treatment systems require adequate drainage to prevent standing water and reduce the risk of flooding and mosquito breeding.

Proper maintenance: Natural treatment systems require regular maintenance to ensure they are functioning properly and to remove accumulated debris.

Q.4

(a) Draw a neat sketch of single stage digester and enlist operational parameters to be maintained.

A single stage digester is a type of anaerobic digester that is used to treat organic waste such as sewage sludge, food waste, and agricultural waste. The basic design of a single stage digester includes a large tank or container, typically made of concrete, in which the waste material is mixed with water and microorganisms. The microorganisms break down the organic matter and produce methane gas as a byproduct.

The operational parameters that need to be maintained for a single stage digester include:

Temperature: The temperature inside the digester should be maintained between 35-38°C for optimal performance of the microorganisms.

pH: The pH inside the digester should be maintained between 7-7.5 for optimal performance of the microorganisms.

Mixing: The waste material in the digester should be mixed regularly to ensure that the microorganisms have access to all the organic matter.

Loading rate: The rate at which the waste material is added to the digester should be controlled to ensure that the microorganisms have enough time to break down the organic matter.

Retention time: The retention time, or the amount of time the waste material is kept in the digester, should be controlled to ensure that the microorganisms have enough time to break down the organic matter.

Gas production: Regular monitoring of gas production is important to ensure that the digester is operating efficiently.

Regular cleaning: Regular cleaning of the digester is important to ensure that it continues to operate efficiently.

(B) Explain the how relationship between different types of bacteria present is important for stabilization in anaerobic process.

In an anaerobic digestion process, different types of bacteria are responsible for breaking down different types of organic matter. The relationship between these different types of bacteria is important for stabilization of the process.

There are three main groups of bacteria involved in the anaerobic digestion process: hydrolytic bacteria, acidogenic bacteria, and methanogenic bacteria.

Hydrolytic bacteria: These bacteria are responsible for breaking down large molecules of organic matter into smaller molecules such as sugars and amino acids. This process is called hydrolysis.

Acidogenic bacteria: These bacteria are responsible for converting the smaller molecules produced by hydrolytic bacteria into volatile fatty acids (VFAs) and other intermediate products. This process is called acidogenesis.

Methanogenic Bacteria: These bacteria are responsible for converting the VFAs and other intermediate products produced by acidogenic bacteria into methane and carbon dioxide. This process is called methanogenesis.

The relationship between these different types of bacteria is important for the stabilization of the process. Hydrolytic bacteria need to be present in sufficient numbers to break down the organic matter. Acidogenic bacteria need to be present in sufficient numbers to convert the smaller molecules produced by hydrolytic bacteria into VFAs and other intermediate products. And methanogenic bacteria need to be present in sufficient numbers to convert the VFAs and other intermediate products into methane and carbon dioxide.

A balance between these three types of bacteria is important for the efficient operation of the process. If the ratio of one type of bacteria to another is not correct, it can lead to an imbalance in the process, which can result in lower methane production and poor process performance.

To maintain a balance between these three types of bacteria, it is important to control the process conditions such as temperature, pH, and organic loading rate. Additionally, regular monitoring of the process and adjusting the conditions as needed can help to maintain the balance between the different types of bacteria.

(C) Draw a neat sketch of up-flow anaerobic sludge blanket reactor and explain it.

up-flow anaerobic sludge blanket (UASB) reactor and explain it.

An UASB reactor is a type of anaerobic digester that is used to treat wastewater and other types of organic waste. The basic design of an UASB reactor includes a cylindrical or rectangular tank with a sloping bottom. The tank is divided into three main zones: the inlet zone, the reactor zone, and the outlet zone.

The inlet zone: The inlet zone is located at the top of the reactor and is where the wastewater or other organic waste is fed into the reactor. The inlet zone is also where the influent is distributed evenly across the reactor.

The reactor zone: The reactor zone is located in the middle of the tank and is where the anaerobic treatment takes place. In this zone, the wastewater or other organic waste is mixed with a mixture of microorganisms and sludge. The microorganisms break down the organic matter, and produce methane as a byproduct.

The outlet zone: The outlet zone is located at the bottom of the reactor and is where the treated water or effluent is discharged. The outlet zone is also where the sludge is separated from the water and collected.

In UASB reactor, the flow of wastewater or organic waste is upward through the reactor, which allows the microorganisms to form a thick blanket at the bottom of the reactor. This blanket, known as the anaerobic sludge blanket, acts as a filter that separates the sludge from the treated water.

One of the main advantages of UASB reactor is its ability to treat high-strength wastewater and organic waste with a high organic loading rate. Additionally, UASB reactor require less energy and have lower operating costs compared to other types of anaerobic digesters.

The operational parameters that need to be maintained for an UASB reactor include:

Temperature: The temperature inside the reactor should be maintained between 35-38°C for optimal performance of the microorganisms.

pH: The pH inside the reactor should be maintained between 7-7.5 for optimal performance of the microorganisms.

Mixing: The wastewater or organic waste in the reactor should be mixed regularly to ensure that the microorganisms have access to all the organic matter.

Loading rate: The rate at which the wastewater or organic waste is added to the reactor should be controlled to ensure that the microorganisms have enough time to break down the organic matter.

Retention time: The retention time, or the amount of time the wastewater or organic waste is kept in the reactor, should be controlled to ensure that the microorganisms have enough time to break down the organic matter.

Gas production: Regular monitoring of gas production is important to ensure that the reactor is operating efficiently.

Regular cleaning: Regular cleaning of the reactor is important to ensure that it continues to operate efficiently.

Q.5

(a) Which factors affect the biological reactions?

There are several factors that can affect the biological reactions in anaerobic digestion process. Some of the main factors include:

Temperature: Temperature plays a crucial role in the anaerobic digestion process. Different types of microorganisms have optimal temperature ranges for growth and metabolism. If the temperature is too high or too low, the microorganisms may not be able to survive, which can lead to a decrease in the rate of digestion.

pH: The pH level of the substrate also plays a crucial role in the anaerobic digestion process. Different types of microorganisms have optimal pH ranges for growth and metabolism. If the pH is too high or too low, the microorganisms may not be able to survive, which can lead to a decrease in the rate of digestion.

Organic loading rate: The organic loading rate (OLR) is the amount of organic substrate that is added to the reactor per unit of time. If the OLR is too high, the microorganisms may not be able to handle the volume of substrate, which can lead to a decrease in the rate of digestion.

Mixing: Proper mixing of the substrate is important to ensure that the microorganisms have access to all the organic matter. If the substrate is not mixed properly, the microorganisms may not be able to break down all of the organic matter.

Hydraulic retention time: The hydraulic retention time (HRT) is the amount of time that the substrate is kept in the reactor. If the HRT is too short, the microorganisms may not have enough time to break down the organic matter.

Retention time : The retention time, or the amount of time the waste material is kept in the digester, should be controlled to ensure that the microorganisms have enough time to break down the organic matter.

Presence of inhibitors: Some substances can inhibit the growth and metabolism of microorganisms, such as heavy metals, high concentrations of salts, and certain chemicals.

Nutrient availability: The availability of nutrients such as nitrogen, phosphorus, and sulfur is also important for the growth and metabolism of microorganisms.

Microbial diversity: The diversity of microorganisms present in the reactor also plays a role in the anaerobic digestion process. A diverse microbial community is more resilient to changes in environmental conditions and is more efficient in breaking down a wide range of substrates.

(B) Differentiate between plug flow reactor and continuous flow stirred tank reactor.

A plug flow reactor (PFR) and a continuous flow stirred tank reactor (CSTR) are both types of continuous flow reactors, but they have some key differences in terms of design and operation.

Design: A PFR is designed so that the fluid flows through the reactor in a plug-like manner, with no backmixing or short-circuiting. The fluid flows through the reactor in a linear path, with no mixing between the inlet and outlet streams. In contrast, a CSTR is designed so that the fluid is well-mixed throughout the reactor, with no distinct inlet or outlet streams.

Residence time: In a PFR, the residence time of the fluid is constant, as the fluid moves through the reactor at a constant flow rate. In a CSTR, the residence time of the fluid is variable, as the fluid is well-mixed throughout the reactor.

Rate of reaction: In a PFR, the rate of reaction is typically first-order with respect to the concentration of the reactant, as the fluid flows through the reactor at a constant flow rate. In a CSTR, the rate of reaction can be zero or higher order with respect to the concentration of the reactant, as the fluid is well-mixed throughout the reactor.

Space time yield: PFRs have a higher space-time yield compared to CSTRs, meaning that they can process more material in a given amount of reactor volume.

Complexity: PFRs are less complex and more cost-effective than CSTRs.

Temperature control: PFRs are more challenging to control the temperature than CSTRs, since the temperature of the fluid is not evenly distributed throughout the reactor.

Applications: PFRs are commonly used in applications such as polymerization, oxidation, and chlorination reactions. CSTRs are commonly used in applications such as fermentation and wastewater treatment.

In summary, PFRs are characterized by a plug-like flow, constant residence time, and first-order kinetics, while CSTRs are characterized by well-mixed flow, variable residence time, and higher order kinetics.

(C) Draw a neat sketch of Bio tower and explain Bio tower

A bio tower is a type of bioreactor that is used to treat waste water and other types of organic waste. The basic design of a bio tower includes a large cylindrical or rectangular tower that is filled with a packing material. The packing material provides a large surface area for microorganisms to grow and treat the waste water.

The bio tower is divided into several sections, including the inlet, the biofilm zone, the growth zone, and the outlet.

The inlet: The inlet is located at the top of the bio tower and is where the waste water or other organic waste is fed into the bio tower.

The biofilm zone: The biofilm zone is located immediately below the inlet and is where the microorganisms first attach to the packing material. In this zone, the microorganisms form a biofilm, which is a thin layer of microorganisms that grows on the surface of the packing material.

The growth zone: The growth zone is located in the middle of the bio tower and is where the microorganisms grow and treat the waste water. In this zone, the microorganisms consume the organic matter in the waste water and produce biomass and byproducts.

The outlet: The outlet is located at the bottom of the bio tower and is where the treated water or effluent is discharged.

In a bio tower, the waste water flows upwards through the tower, which allows the microorganisms to form a biofilm on the packing material. The biofilm effectively removes contaminants from the waste water. Additionally, the bio tower can be used in different types of wastewater treatment such as biological nutrient removal, chemical removal and even heavy metal removal.

The operational parameters that need to be maintained for a bio tower include:

Temperature: The temperature inside the bio tower should be maintained within the range that is suitable for the microorganisms used.

pH: The pH inside the bio tower should be maintained within the range that is suitable for the microorganisms used.

Mixing: The waste water in the bio tower should be mixed regularly to ensure that the microorganisms have access to all the organic matter.

Loading rate: The rate at which the waste water is added to the bio tower should be controlled to ensure that the microorganisms have enough time to break down the organic matter.

Retention time: The retention time, or the amount of time the waste water is kept in the bio tower, should be controlled to ensure that the microorganisms have enough time to break down the organic matter.

Q.5

(a) Differentiate between homogeneous and heterogeneous reactions with example.

Homogeneous and heterogeneous reactions refer to the physical state of the reactants and products in a chemical reaction.

Homogeneous reactions: In a homogeneous reaction, all the reactants and products are in the same physical state, usually a gas or liquid. An example of a homogeneous reaction is the reaction between hydrogen gas and oxygen gas to form water vapor:

2H2(g) + O2(g) → 2H2O(g)

Heterogeneous reactions: In a heterogeneous reaction, the reactants and/or products are in different physical states, such as a solid, liquid, or gas. An example of a heterogeneous reaction is the reaction between iron and sulfur to form iron sulfide:

Fe(s) + S(s) → FeS(s)

In this reaction, the reactants iron and sulfur are both solids, and the product, iron sulfide, is also a solid.

Another example of heterogeneous reactions is catalytic reactions, in which a solid catalyst is used to speed up a reaction between two gases or a gas and a liquid. In this case, the catalyst is a solid, while the reactants and products are in a different phase, such as gas or liquid.

In summary, homogeneous reactions occur when all the reactants and products are in the same physical state, usually a gas or liquid. Heterogeneous reactions occur when the reactants and/or products are in different physical states, such as a solid, liquid, or gas.

(B) Differentiate between packed bed reactor and fluidized bed reactor.

Packed bed reactor and fluidized bed reactor are two types of reactors that are used in various chemical and biological processes. They differ in the way that the solid particles are suspended in the fluid.

Packed Bed Reactor: In a packed bed reactor, a bed of solid particles is packed into a cylindrical vessel. The fluid (gas or liquid) flows through the bed of particles in a linear flow pattern. The solid particles are not agitated and remain in a fixed position. The rate of reaction is controlled by the movement of the fluid through the bed of particles, and the contact between the fluid and the solid particles.

Fluidized Bed Reactor: In a fluidized bed reactor, a bed of solid particles is suspended in a fluid (gas or liquid) that is flowing through the reactor. The fluid is pumped into the reactor at a rate that is sufficient to suspend the solid particles and create a fluid-like state. The solid particles are agitated and move freely within the reactor. The rate of reaction is controlled by the movement of the fluid and the solid particles, and the contact between the fluid and the solid particles.

Applications: Packed bed reactors are commonly used in catalytic reactions, adsorption, and gas absorption processes. Fluidized bed reactors are commonly used in combustion, gasification, and chemical synthesis processes.

Advantages: Packed bed reactors have a higher pressure drop across the bed and also have a higher space-time yield. Fluidized bed reactors are more effective for heat and mass transfer, and also have high conversion efficiency.

In summary, packed bed reactors are characterized by a packed bed of solid particles, linear flow pattern, and fixed position of the solid particles. Fluidized bed reactors are characterized by a fluidized bed of solid particles, fluid-like state, and free movement of the solid particles. Packed bed reactors are more suitable for applications that require a high pressure drop and high space-time yield. Fluidized bed reactors are more suitable for applications that require high heat and mass transfer and high conversion efficiency.

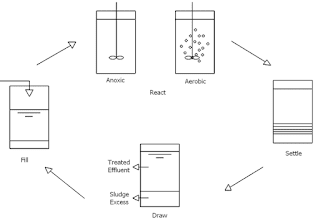

(C) Draw a neat sketch of Sequential batch Reactor and explain it.

A Sequential batch reactor (SBR) is a type of wastewater treatment system that combines the features of both batch and continuous flow systems. It is a tank that is filled with a mixture of microorganisms and wastewater. The tank is operated in cycles, with each cycle consisting of four distinct phases: fill, react, settle, and discharge.

Fill: During the fill phase, wastewater is added to the tank to bring it to its working volume.

React: During the react phase, the microorganisms consume the organic matter in the wastewater and produce biomass and byproducts. The microorganisms are supplied with oxygen through mechanical aeration or natural diffusion.

Settle: During the settle phase, the microorganisms and other suspended solids settle to the bottom of the tank, forming a sludge blanket. The clear liquid on top is called the effluent.

Discharge: During the discharge phase, the settled sludge is removed from the tank, and the clear liquid is discharged as treated effluent.

SBRs are used for the treatment of wastewater from various sources, such as municipal wastewater, industrial wastewater, and even leachate from landfills. The SBR system is flexible and can be adapted to the specific needs of the wastewater stream. Additionally, the SBR system is simple to operate, maintain, and control, making it a cost-effective solution for wastewater treatment.

Operational parameters that need to be maintained for an SBR include:

Temperature: The temperature inside the SBR should be maintained within the range that is suitable for the microorganisms used.

pH: The pH inside the SBR should be maintained within the range that is suitable for the microorganisms used.

.jpeg)

.jpeg)

.jpg)

0 Comments